松井アーキメタル舞鶴工場|Matsui Archmetal Maizuru Factory

2020|Factory|ショールーム機能を併せ持つ屋根材の成形工場

海岸線から約500mの敷地に建つこの建築は、それ自体が商品見本であり、年月を経て製品の耐候性を明らかにする。

一般に、工場建築は厳しい予算管理が必要となるが、経済性を高めながら、それと異なった価値基準である、 意味性を高めることを同時実現しようと考えた。使用材料の選定から、スパンや階高、下地ピッチの綿密な調整といった定量的なコントロールと、光や風といった外部環境と作業に適した安全な内部環境を調停する定性的なコントロール、この二つは物理的、客観的な判断基準によってなされるが、それらと矛盾させずに、私たちの工場は唯一の価値を持つ、と思えるような精神的、主観的な豊かさを重ね合わせたい、ただ役に立つものであることを乗り越えたいと考えた。その具体的方法として、経営者や職員が取引先や来客に対して、製造環境や製品の良さをプレゼンテーションできる動線を忍ばせることで、この工場に意味的価値を持たせようとしている。言い換えれば、工場であり展示場でもある建築を設計しようとした。

その際、工場に、展示場として必要な室や部材を付加するのではなく、工場を展示場だと読み替えられるような両義性を持たせることでそれを実現しようとしている。

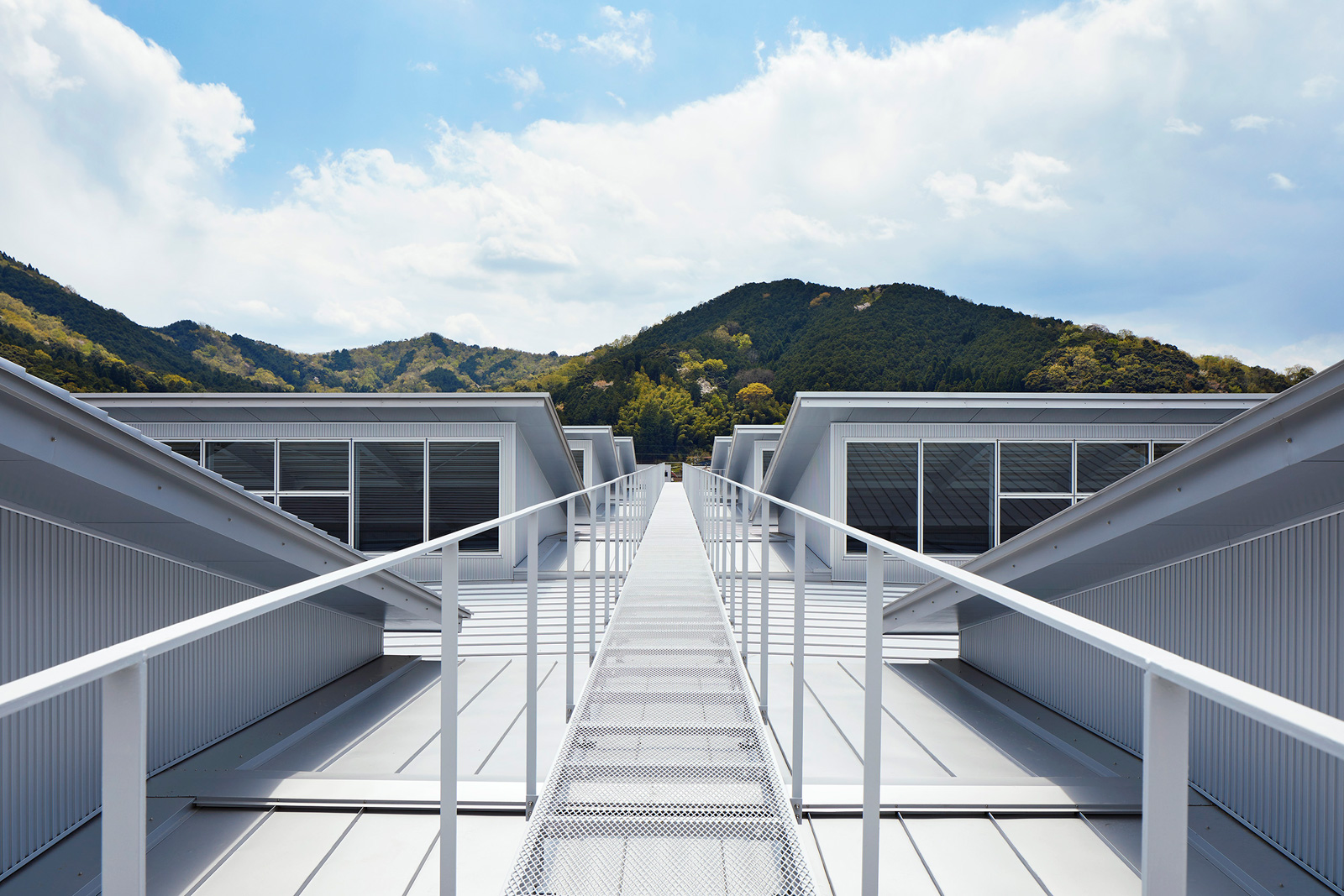

ルビンの壺という有名な図形がある。デンマークの心理学者ルビンが考案した図形で、向き合った二人の顔にも見えるし、大きな壺にも見えるという白黒の図形である。見慣れてくれば、知覚を自在に切り替え見たい方の図形として認識することができる。ルビンの壺のように、この建築は、工場だと思えば工場だが、来客を案内する際には展示場として認識することができる。事務棟は受付やホワイエ、来客をもてなすカフェ、作業場は実演展示エリア、ストックヤードは常設展示エリア、 屋上のメンテナンス用ブリッジは屋外鑑賞動線に変わる。

工場棟の大屋根の上には8枚の越屋根を設置した。日本では明治時代より工場建築に取り入れられてきたのこぎり屋根と同様の原理で、北側から安定した間接光を取り入れ、通風を確保している。屋上レベルでは、大屋根から立ち上がった越屋根が、群建築のように感じられるよう、越屋根を1スパン置きに設置し、中央にブリッジを通した。ノコギリ屋根の効能はそのままに、ギザギザの屋根から、大屋根の上に浮かぶ8枚の屋根へと形式と意味を変換している。それぞれの越屋根を異なった屋根材で葺いているため、写真や小サンプルでは分かり難い違いを間近で見学することができる。

越屋根の開口部を通して、 屋上から工場内が感じられる。越屋根に使用されている材料が、今まさに成型されている現場と上下につながっていることで、トレーサブルな感覚を生み、ブリッジの先端からは舞鶴西港の海運、陸運が綾なすダイナミックな風景が一望できる。

- 所在地

- 舞鶴市

- 主用途

- 工場

- 規模・構造

- 建築面積:2,282.15㎡/延床面積:2,360.56㎡/法定延床面積:2,355.64㎡ |工場棟|鉄骨造2階建/1階:1,885.39㎡, 2階:240.64㎡, PH階:6.10㎡ |事務棟|木造2階建/1階:107.54㎡, 2階107.54㎡ |少量危険物貯蔵庫|鉄骨造平屋/1階:8.00㎡ |消化ポンプ室|鉄骨造平屋/1階:5.35㎡

- 寸法

- |工場棟|最高高:13,044mm/軒高:12,515mm/階高 1階:4,845mm 2階:4,735mm/主要なスパン:16,450×6,500mm |事務棟|最高高:5,830mm/軒高:5,276mm/階高 1階:2,437mm, 2階:2,689mm/主要なスパン:3,640×3,640mm

- 敷地条件

- 工業専用地域 /22条区域 /臨港地区

- 構造設計

- 柳室純構造設計

- 設備設計

- 創見社設備設計

- 施工

- 株式会社 吉住工務店

- 写真

- 矢野紀行写真事務所

For the relocation and expansion of galvanized steel roofing factory in the harbor of Northern Kyoto, programs such as exhibition space and a factory tour route are incorporated into its production space and a sales office. This new factory’s roofs and walls are made of building materials manufactured or handled by the company, as if it replicated itself on its own. Standing just 500 m away from the coastline, the factory shows its weathering quality over years, like product samples, exposed against salty sea breeze.

Along with economic efficiency under strict budget control of the factory construction, we focused on the building’s meaningfulness, in which client finds unique value and emotional richness beyond function. For that we hided a line of presentation for visitors under its production space, in order to make architecture that is both a factory and an exhibition hall. Here what we pursued is to make the factory readable as an exhibition hall, rather than adding rooms and materials. We conceived it like Rubin’s vase, which is a vase but also is readable as two faces of people, depending on perception for figure and ground: this building is a factory if you see it so, but it can be recognized as an exhibition space when guiding visitors. Or the office building will be a reception desk, a foyer, and a cafe that welcome visitors, the workshop will be a demonstration area, the stockyard will be a permanent exhibition area, and the rooftop maintenance bridge will be an outdoor viewing space.

Eight monitor roofs stand on the main roof and gain indirect light and air from the north side, which interpret sawtooth roof, typical for factory construction in Japan. Unlike sawtooth roof, these roofs are but placed every other span so that they look like a group of buildings standing with certain distance. When they are seen close from the bridge on top of the main roof, you will notice that each monitor roof is cladded in different roofing materials. Here, this rooftop works as an exhibition space where planner can see different products of this factory like mock-ups in a view.

When you stand on the roof, you can literally see the whole lifecycle of the products at a glance: the production process is shown below through the opening of the monitor roof, the finished products are showcased all over the skin of the factory, and the transportation can be looked over the building as a backdrop, where Maizuru West Harbor, which is an international industrial port and the products are shipped all around the world from here, is located just behind the site.

translated by Tota Goya

Completion Year:2020

Gross Built Area: 2,360.56㎡

Project location: Maizuru, Kyoto

Lead Architects: Kenzo Makino & Associates

Structural Design: Jun Yanagimuro Structural Design

HVAC: SOKENSYA CO.LTD

Construction: YOSHIZUMI CO., LTD

Photo credits: Toshiyuki Yano